About the Centre

The Siemens CoE in Manufacturing, established in 2020 at Visvesvaraya National Institute of Technology, Nagpur Maharashtra, operates with a primary focus of creating a robust technical education eco-system through its experience in industrial products and services. There are 11 sophisticated Laboratories for Product Design and Validation, Advanced Manufacturing, Test and Optimization, Automation, Process Instrumentation, Mechatronics, CNC,Robotics, Reverse Engineering, Internet of Things and Smart Factory which provides opportunity for promising innovations. This multi-faceted unique center offers Skill Development Courses, Internships, Research & Development Assistance and Industrial Consultancy Services across various sectors. - Space and Seed Funding from VNIT, a Deemed to be University offering B Tech, M Tech and Ph D Programmes in various disciplines of Engineering, Science, - Operational Expertise from Siemens, a pioneer in the field of eLearning in Industry 4.0 – CNC, Robotics, Automation, Mechatronics, Smart Factory, serving the upskilling and training needs of both academia and corporate India.

V. R. Jamdar Siemens Centre of Excellence

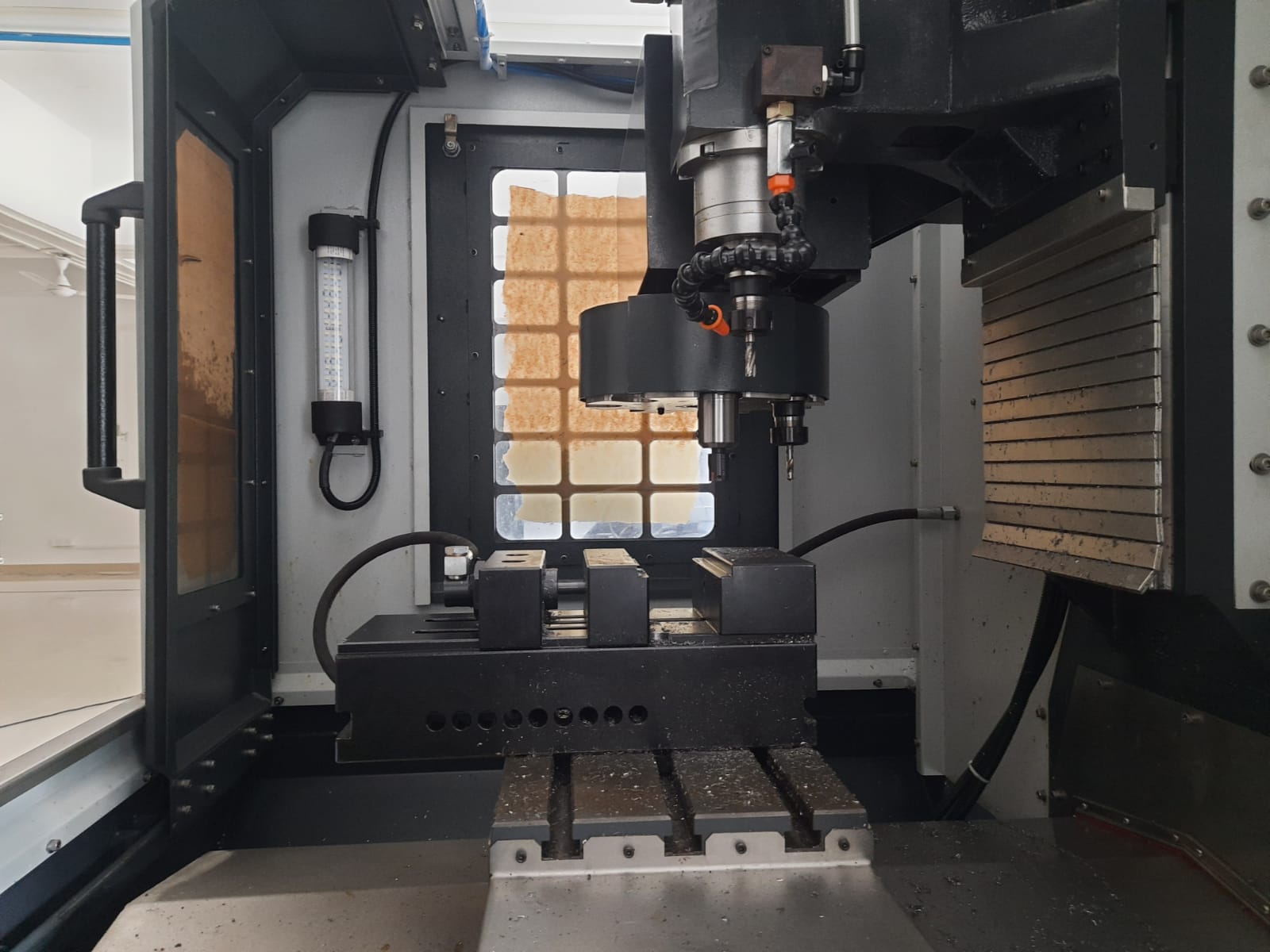

VNIT Nagpur has started a setting up in the COE in the field of Industry 4.0 and Digitalization with thrust on Biomedical Engineering, Robotics, and Smart Manufacturing. The COE is in collaboration with Siemens Software India Pvt. Ltd. as a Technology partner. the total outlay of this COE is 187 Cr out of which 88% is shared by Siemens and 3D Engineering. CoE has 11 Labs out of which 5 are Software Labs and 6 are Hardware Labs. These labs are focus on Reverse Engineering, Mechatronics, Instrumentation, 5 Axis Simultaneous CNC, Robotic welding, Smart Manufacturing, IoT, Design and Validation, and Automation.

Director's Message

I am glad to share that VNIT Nagpur has setup Siemens Centre of Excellence in Industry 4.0 and Digitalization. It is a multidisciplinary, industrial collaboration that focuses on developing “Skill Excellence” for Academia and Industry. This CoE is envisioned as a link that aligns industry requirements with technical education to make industry-ready engineering graduates.

Siemens has designed various learning modules of different durations for Engineering, Polytechnic and ITI students for developing technical skills, enhancing knowledge, and opening up recruitment and start-up opportunities. Moreover, the aim of the CoE is to offer learning opportunities for industry personnel, technical teachers, practicing engineers and researchers. These learning tracks are jointly certified by Siemens and VNIT Nagpur. The CoE shall also offer consultancy services to Industries in automation, product development, process optimization, shop floor design, robotics, smart manufacturing, Internet of Things, Reverse Engineering etc. and in skill enhancement of existing employees. I appeal to all the stake holders to make maximum use of this state of the art technology available at VNIT Nagpur.

COE Program Highlights

World Class Infrastructure

Certification from VNIT & Siemens

Placement Assistance

Bridging Academics & Industry

Exposure to Cross Industry Applications

Internship

Executive Director & CEO at Triveni Turbine Ltd

(Harvard Delegate (HPAIR) ,TEDx AixTalk Speaker ,System Design Intergrator ,Young Ambassador India DAAD,United Nations Volunteer)

Assistant Professor- Shri Ramdeobaba College of Engineering and Management

Transferscout Faculty of Mathematics and Natural Sciences, University of Cologne, Germany

Manager at Production Modeling India Pvt Ltd (PMI)

Professor ,Defence Institute of Advanced Technology Pune

Assistant Professor , Amity University, Chhattisgarh.

Executive Director / Partner - ASPAC Head of Infrastructure KPMG, Singapore

Manager- Foundry. M/S Perfect Alloy Components (P) Ltd

Director ( National Academy of Defence Production) NADP Nagpur

Senior Executive - CEO Office, Solar Industries India Ltd

Our Partners

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)